Artem Slizunov

Facebook

Вконтакте

О себе и о ремонте

Награды и дипломы Master in Architecture and Urbanism / London Metropolitan University

Услуги

Ограничение при добавлении услуги

Вы исчерпали число услуг которые можно добавить в профиль на этом тарифе.

Чтобы увеличить лимит необходимо перейти на другой тариф.

Чтобы увеличить лимит необходимо перейти на другой тариф.

artem slizunov

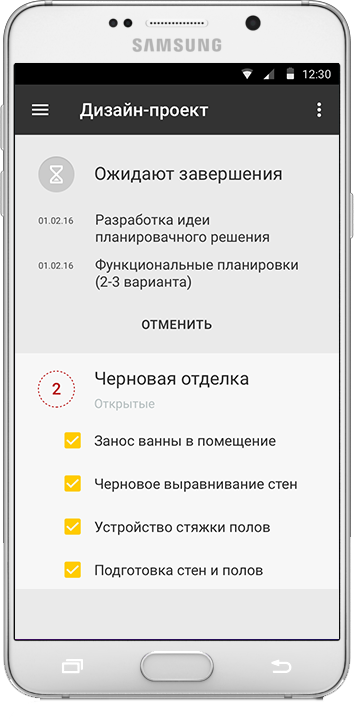

Заказы

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

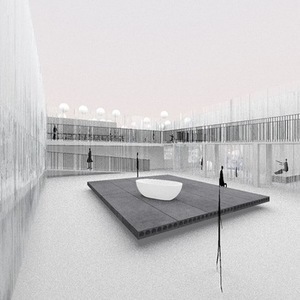

The Russian Pavilion in Venice: Between Past and Future<br/><br/>June 10 – June 29, 2014<br/><br/>Garage Museum of Contemporary Art, Moscow<br/><br/>The exhibiting of Russian art at the Venice Biennale dates back to the very first show in 1895. Back then, artists from around the world would present their works in the halls of the central pavilion. It was thanks to the Russian exhibition’s great success at the 7th Biennale in 1907, and after Czar Nicolas II’s visit to Italy in 1909, that Russia was approached with an offer to build a separate pavilion. Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

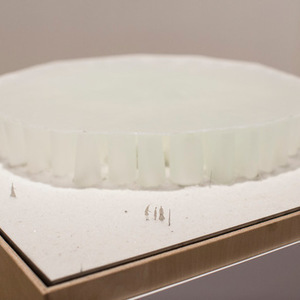

museum az / музей художника зверева 2013<br/> Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

mannequin to demonstrate hats / togather with vladimir kuzmin Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

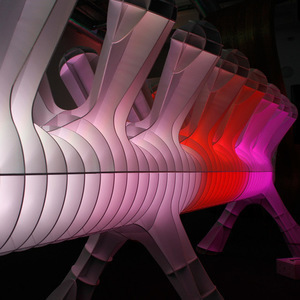

location: Derbenevskaya Nab. 7, Moscow<br/><br/>The office of the company “Euro<br/>Kommerz” in one of the historical<br/>buildings on the territory of a<br/>former Moscow Cotton-Printing Factory,<br/>located on Derbenevskaya Nab.<br/><br/>This office space measures 137 metres<br/>in length, 24 metres in width and more<br/>than 4 metres in height, and is divided<br/>into two sections by a partition.<br/>The walls are made of brick. Parallel<br/>to the long side on three axes, there<br/>are cast-iron columns acting as vertical<br/>supports. Built in the mid-19th<br/>century.<br/><br/>The main architectural solution is<br/>the metal construction of the pedestrian<br/>entresol with an adjoining ramp<br/>and staircases. The overall length<br/>of the assembled construction is 102<br/>metres.<br/><br/>Because the design, planning and<br/>installation of the project had to<br/>be done to a tight time schedule,<br/>maximum use was made of modern design<br/>technology and of the laser processing<br/>of sheet material (sheet steel, MDF panels, oak veneer sheets) and of<br/>the profile bending of sheet material (metal). Turning, milling, polishing<br/>work was used only in especially important places which are subject to maximum<br/>pressure (the stanchions of the entresol and of the ramp, the transition<br/>hubs, the elements connecting the modules of the entresol and so on).<br/>All welding work was carried out in special frames to guarantee the maximum<br/>accuracy and avoid the thermal deformation of the modules. All the fasteners<br/>(with the exception of the handrail in the entresol) are concealed. At all<br/>the joins of the entresol modules – the zones of the stanchions, a thermodampening<br/>layer of caoutchouc has been used to compensate for expansion of<br/>the construction of the entresol during temperature changes. The metal surfaces<br/>are corroded (rusty) steel and have a chemically created patina, fully<br/>imitating the existing cast-iron columns.<br/><br/><br/><br/>architects: <br/>Artem Slizunov, Vladimir Kuzmin<br/><br/>Implementation:<br/>Company Single Solution [singlesolution.ru]<br/> Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

work space company "state development" Выполненная работа

artem slizunov

, , д.

-комнатная квартира, м2

ремонт

Стоимость работ (не задано)

Стоимость материалов (не задано)

Описание ремонта

Выполненная работа